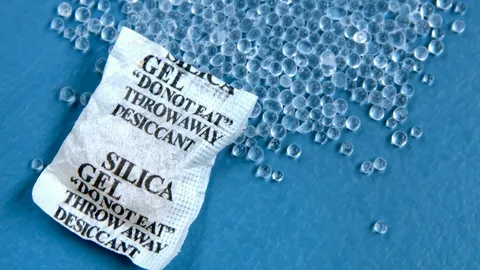

Silica-Gel Desiccants are commonly used for moisture absorption in various industries and applications. They are small, porous packets filled with silica-gel, a highly absorbent form of silicon dioxide. In this blog post, they will delve into silica gel desiccant and explore everything you need to know about their uses, benefits, and safety considerations.

Understanding Silica-Gel Desiccants

Silica-Gel Desiccants function through a phenomenon known as adsorption, where water vapour in the air adheres to the surface of the silica-gel particles without becoming part of the material itself. This distinct mechanism is facilitated by the unique physical structure of silica-gel, composed of a network of interconnected pores that provide an extensive surface area for moisture to collect.

Despite being called a ‘gel’, silica-gel is solid and granular, making it an efficient desiccant for various applications. Its ability to adsorb a significant amount of moisture relative to its weight and maintain this capacity over a wide range of temperatures makes Silica-Gel Desiccants a preferred choice for controlling environmental humidity and safeguarding products and goods from moisture-induced damage.

The Science behind Moisture Absorption

The efficacy of Silica-Gel Desiccants in moisture absorption is rooted in their microscopic structure. These desiccants contain a vast network of tiny pores, presenting an expansive surface area interacting with water vapour in the air. When ambient air permeates the silica-gel, the silica particles attract and hold the water molecules due to a process known as physical adsorption.

This phenomenon is governed by the Van der Waals force, a weak electrical force that draws the water molecules to the surface of the silica-gel, allowing it to capture and retain moisture efficiently.

Unlike chemical absorption, where the absorber undergoes a chemical change, physical adsorption ensures the silica-gel remains unchanged, maintaining its structure and ability to absorb moisture repeatedly. This molecular interaction underpins the silica-gel’s prowess as a desiccant, making it an invaluable tool in controlling humidity and protecting against moisture-related degradation.

Safety Considerations and Myths Debunked

Whilst Silica-Gel Desiccants are widely considered safe for various applications, there are essential safety considerations to remember. Contrary to popular belief, silica-gel itself is non-toxic; however, the packets often carry warning labels advising against ingestion mainly due to the choking hazard they pose, particularly to children and pets.

Additionally, some silica-gel packets may be coated with indicating dyes that change colour when saturated, and these dyes can sometimes be toxic if ingested in large quantities. It is, therefore, prudent to handle these materials with care and ensure they are kept out of reach of vulnerable individuals. Despite these precautions, the inherent properties of Silica-Gel Desiccants do not pose a chemical hazard, debunking myths about their toxicity and reaffirming their safety profile in moisture control applications.

Common Uses of Silica-Gel Desiccants

Explore the various applications and uses of Silica-Gel Desiccants. Learn how they help in moisture control and preservation.

Protecting Electronics and Devices

Silica-Gel Desiccants protect electronic devices and components from moisture-induced damage. They absorb excess humidity, preventing corrosion, condensation, and other moisture-related issues that can lead to device malfunction or failure.

Pharmaceuticals and Healthcare Products

Moisture control is vital in the pharmaceutical industry to ensure the stability and efficacy of medicines. Silica-Gel Desiccants are used in packaging to maintain an optimal dry environment, protecting products from degradation, clumping, or chemical alteration due to humidity.

Food Preservation

In the food industry, Silica-Gel Desiccants extend the shelf life of dry foods by preventing the growth of mould and bacteria, which thrive in moist conditions. They are particularly useful in packaging spices, nuts, and dried fruits, where moisture control is essential for maintaining freshness and flavour.

Archival Storage

Silica-gel is used to store and preserve important documents, photographs, and artefacts. By controlling the relative humidity in storage environments, silica-gel helps prevent paper degradation, photograph fading, and historical item deterioration.

Transport and Storage of Goods

During the transportation and storage of goods, particularly those sensitive to moisture, Silica-Gel Desiccants absorb excess humidity that could accumulate in shipping containers or storage boxes. This application is critical in preventing mould, rust, and other moisture-related damage to textiles, leather goods, and machinery parts.

Environmental Impact and Disposal

Silica-Gel Desiccants are considered environmentally benign due to their inert nature and recyclability, which aligns with sustainable waste management practices. With their reusability, they have a minimal environmental impact when disposed of correctly. It is essential to follow local disposal regulations to avoid potential ecological consequences. Expired or saturated silica-gel packets should not be carelessly thrown away in household waste but instead, where available, sent to specialised recycling centres capable of processing silicon dioxide materials.

Additionally, recycling these desiccants by drying out their absorbed moisture extends their usefulness and reduces the need for frequent replacements, thus reducing waste. Such practices promote responsible consumption and resource conservation, emphasising the importance of environmental stewardship in handling Silica-Gel Desiccants.

Innovative Applications of Silica Gel

Silica-Gel Desiccants are finding their way into groundbreaking applications beyond their conventional uses. In 3D printing, silica gel is utilised to maintain an optimal moisture-free environment, enhancing the quality and durability of printed objects. Research indicates that incorporating silica-gel in filament storage significantly reduces the incidence of print failures due to moisture.

Another inventive use of silica-gel is in renewable energy systems, particularly in solar panels and battery storage, where it protects sensitive components from humidity, thereby improving efficiency and lifespan. Horticulture also benefits from silica-gel’s properties, which aid in preserving seeds during storage by preventing mould growth and germination triggered by excess moisture. These innovative applications underscore the versatility of Silica-Gel Desiccants and their potential to contribute to advancements across a broad spectrum of industries.

How to Reuse and Reactivate Silica-gel Packs

Reactivating silica-gel packs is a straightforward process that significantly extends their usability. Begin by preheating your oven to a temperature of 100-120°C. Spread the silica-gel packs on a baking tray in a single layer, ensuring they are not overlapping. Place the tray in the oven for 1-2 hours. The gentle heat will drive the moisture out of the silica beads, effectively restoring their drying capacity.

It’s essential to monitor the process to prevent overheating, which could degrade the silica-gel. Once dry, remove the packs from the oven and allow them to cool before reusing. This method is an efficient way to recycle silica-gel packs, promoting sustainability by reducing waste.

Comparing Silica-gel with Other Desiccants

When comparing silica-gel to other desiccants like clay or calcium chloride, it’s essential to understand their unique properties and applications. Silica-gel is renowned for its high moisture adsorption capacity, making it particularly effective in various temperatures. It is also chemically inert, posing no risk of damaging the products it protects. Clay desiccants, whilst more cost-effective, offer a lower adsorption capacity and are less effective in extreme conditions.

On the other hand, calcium chloride can absorb a substantial amount of moisture but runs the risk of liquid leakage as it turns into a brine, which might not be suitable for all applications. Therefore, the choice of desiccant largely depends on the specific requirements of the task, including the desired level of moisture control, temperature conditions, and safety considerations.

The Role of Silica-gel in Museum Preservation

In museums, Silica-Gel Desiccants are integral to preserving artefacts and artworks. The controlled environment created by these desiccants mitigates the risk of damage caused by fluctuations in humidity. This stability is crucial for maintaining the integrity of a wide range of materials, including paper, fabric, leather, and wood, which can all suffer from moisture-induced degradation.

Studies have shown that maintaining consistent relative humidity levels can significantly reduce the deterioration rate of these sensitive items. By absorbing excess moisture, silica-gel helps to prevent the onset of mould and mildew, which are common culprits in the degradation of historical pieces. Consequently, Silica-Gel Desiccants have become a standard conservation tool in the museum industry, ensuring the longevity and preservation of invaluable cultural heritage.

Silica-gel in Food Packaging

Silica-Gel Desiccants are essential to ensuring the longevity and safety of food products by meticulously managing moisture levels within the packaging. Their inclusion in food packaging directly inhibits bacterial and fungal growth, pivotal factors in food spoilage and degradation. This application of Silica-Gel Desiccants is especially beneficial in preserving dried foods, such as jerky, spices, and crisps, where maintaining low moisture content is critical to freshness and flavour retention.

Using silica-gel in food packaging enhances product shelf life and upholds the quality, ensuring that food items remain safe for consumption over extended periods. This approach underscores the critical role of moisture control in food safety and preservation strategies.

Choosing the Right Silica-gel for Your Needs

Discover how to choose the best silica-gel for your requirements. Learn about types, sizes, and uses for effective moisture absorption.

Determine Moisture Sensitivity

Evaluate how sensitive your items are to moisture. Items with high moisture sensitivity require silica-gel with a higher adsorption rate.

Assess the Volume of Space

Consider the size of the space or container. Larger spaces may need more silica-gel or packets with larger bead sizes for effective moisture control.

Indicator vs Non-Indicator

Decide if you need to indicate silica-gel, which changes colour when saturated, to monitor moisture levels visually. This is particularly useful in situations where regular checks are feasible.

Operating Temperature Range

Ensure the silica-gel type you choose is effective within your application’s specific temperature range, as some variants have optimal performance at different temperatures.

Environmental Considerations

For those prioritising environmental sustainability, look for reusable silica-gel products that can be easily reactivated, reducing waste and enhancing eco-friendliness.

The Future of Silica-gel Technology

As the demand for more efficient moisture control solutions increases, ongoing research focuses on improving Silica-Gel Desiccants’ physical and chemical properties. Innovative enhancements aim to increase adsorption rates, extend lifespan, and expand the range of operational temperatures, making silica-gel even more versatile.

Additionally, the development of eco-friendly, biodegradable silica-gel s is gaining traction, promising to reduce environmental impact further. These advancements in silica-gel technology are poised to revolutionise industries reliant on moisture control, offering more sustainable and effective solutions to meet future needs.

Tips for Handling and Storing Silica-Gel Desiccants

To maintain the efficacy of Silica-Gel Desiccants, they should be kept in an environment that is both cool and devoid of moisture. Direct exposure to sunlight or damp conditions can compromise their adsorption capabilities. It is advisable to store them in an airtight container when they are not being actively used to prevent premature saturation.

Regular inspection of the desiccants for signs of moisture saturation is recommended to ensure they remain functional. By adhering to these guidelines, you can prolong the useful life of Silica-Gel Desiccants and ensure they continue to provide effective moisture control.

Conclusion

Silica gel desiccants offer a robust and efficient solution to moisture control across many sectors, underpinning their critical role in preserving the integrity and longevity of countless products. By leveraging the unique adsorptive properties of silica-gel, industries from pharmaceuticals to renewable energy can mitigate the detrimental effects of humidity. Embracing correct usage and reactivation practices enhances the sustainability and efficacy of these desiccants, highlighting their indispensability in maintaining optimal humidity levels. Their safety, versatility, and environmental compatibility further solidify their status as an indispensable resource in moisture management strategies.

FAQ’S

Can silica gel desiccants be reused?

Silica gel desiccants packs can be reactivated by gently heating them in an oven to drive out absorbed moisture, allowing them to be reused.

Are silica gel desiccants safe for use with food?

Silica gel is considered safe in food packaging to control moisture and extend shelf life, although direct contact with consumables should be avoided.

How do silica-gel desiccants absorb moisture?

They work through a process of adsorption, where water vapour from the air is trapped in the pores of the silica-gel.

What’s the difference between indicating and non-indicating silica-gel?

Indicating silica-gel changes colour when saturated, providing a visual cue that it needs to be replaced or reactivated, whereas non-indicating silica-gel does not.

How much silica-gel is needed to protect a specific item?

The amount required depends on several factors, including the item’s moisture sensitivity, the space volume, and the existing humidity levels.

| Other Good Articles to Read |

| skank blogs |

| unreal blogs |

| tba blogs |

| all city forums |

| dany blogs |

| refuge blogs |

| the music blogs |

| key forums |

| the big blog theory |

| joe blogs |

| blogs 4 me |

| Blogs Emon |

| Related Business Listings |

| Contact Directory |

| Local Business Profiles |